Apex Machining Technologies LLC

Apex Machining Technologies LLC is a CNC machining supplier based in the San Francisco Bay Area. We focus on precision milling and turning of both rotating and prismatic parts, providing stable quality and lead times for prototypes and small to medium-sized production.

With hands-on production and assembly experience, we understand real-world installation and performance requirements. We aim to be a responsive, long-term machining partner for engineering teams and manufacturers.

- 3-Axis & 4-Axis CNC milling

- CNC turning for shafts, bushings, flanges and fittings

- Custom aluminum, steel, stainless and brass components

- Prototyping and small-batch production

- Tapping, threading, drilling, boring

- Basic assembly & dimensional inspection

We review each RFQ for manufacturability and highlight risks on tolerances, wall thickness, tool access and surface finish before production.

Have a drawing ready? Send it for a fast CNC quote →

- Vertical machining centers – for aluminum, steel and stainless steel parts

- CNC turning centers – for shafts, bushings, flanges and custom fittings

- Multi-face and angled machining with project-specific fixturing

- Stable CNC controls compatible with standard CAD/CAM workflows

- Standard measuring tools – calipers, micrometers, thread gauges

- Consistent precision for both rotating and prismatic components

- Efficient setup for low to mid-volume production runs

- Clean, organized shop focused on reliability and repeatability

Shop overview – vertical machining centers and CNC turning in a clean layout.

Shop overview – vertical machining centers and CNC turning in a clean layout.

CNC turning center – ideal for shafts, bushings and flanges.

CNC turning center – ideal for shafts, bushings and flanges.

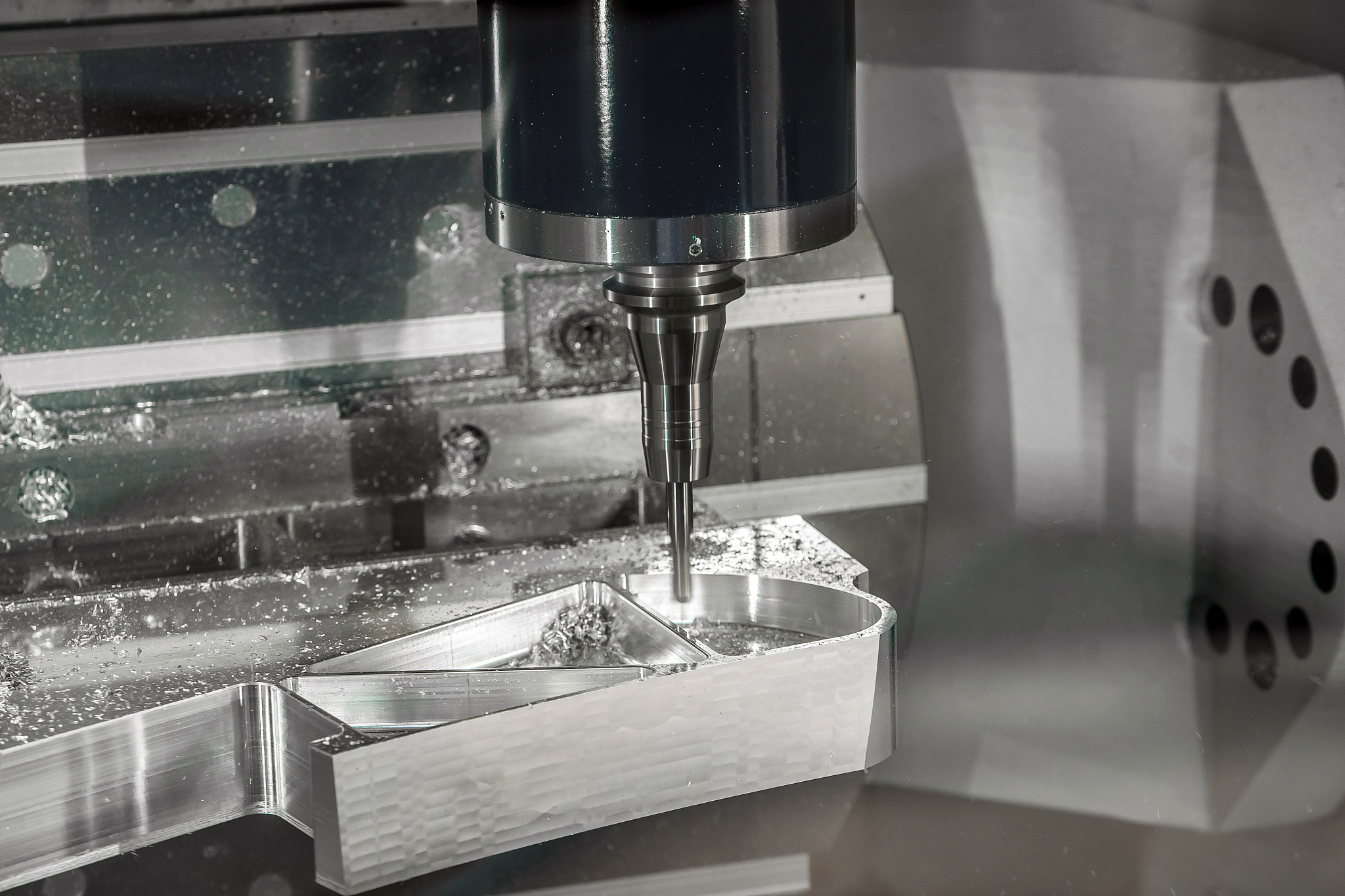

Milling with coolant – stable cutting and improved surface quality.

Milling with coolant – stable cutting and improved surface quality.

Precision finishing – consistent profiles and clean surfaces.

Precision finishing – consistent profiles and clean surfaces.

Parts similar to these? Share your BOM and drawings →

Stainless steel threaded fittings – concentricity and surface finish controlled.

Stainless steel threaded fittings – concentricity and surface finish controlled.

Flanged shafts – for support, mounting and transmission interfaces.

Flanged shafts – for support, mounting and transmission interfaces.

Precision shafts and pins – small, tight-tolerance rotating parts.

Precision shafts and pins – small, tight-tolerance rotating parts.

Mixed milled and turned components for assemblies and mechanisms.

Mixed milled and turned components for assemblies and mechanisms.

Aluminum brackets and housings – lightweight structural components.

Aluminum brackets and housings – lightweight structural components.

Machined flanges – flatness and hole positions held to spec.

Machined flanges – flatness and hole positions held to spec.

Blocks and covers – multi-face machining in one setup.

Blocks and covers – multi-face machining in one setup.

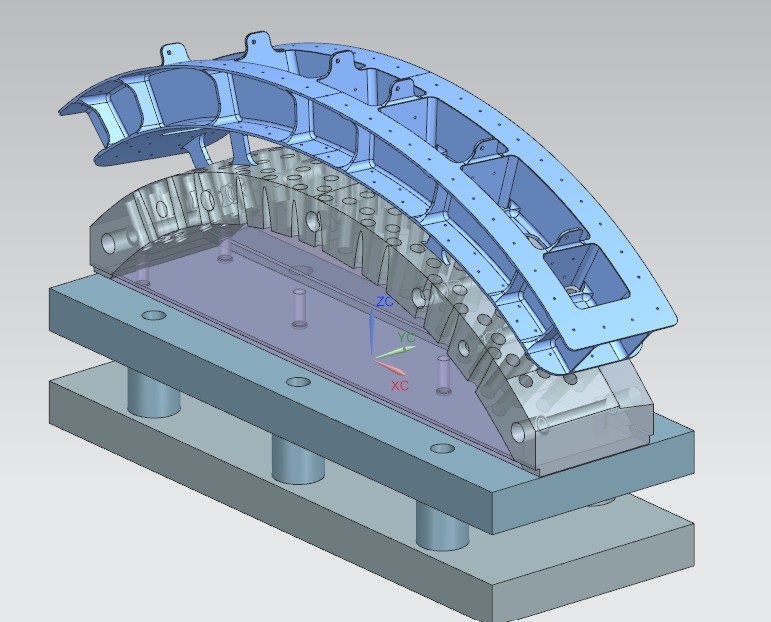

Custom fixture concept – curved clamping for profile parts.

Custom fixture concept – curved clamping for profile parts.

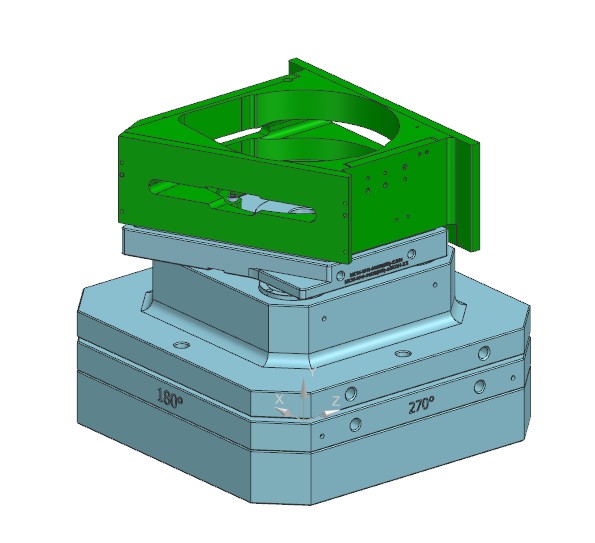

Rotary base fixture – supports multi-angle machining.

Rotary base fixture – supports multi-angle machining.

If your parts look similar to these, attach your drawings and get a tailored quote →

Brackets, anchors, supports, connection parts.

Frames, plates, shafts, motion components.

Metal frames, hinges, mounting adapters.

Housings, flanges, collars, custom fittings.

Low-volume precision components and assemblies.

Simple fixtures and supports on a project basis.

Not sure if your application fits? Share your requirements and we will review your RFQ →

Email: apexfabone@gmail.com

Location: San Francisco Bay Area, California, USA

Available for flexible cooperation with U.S. and international customers.

If you share your drawings and basic requirements, we will respond with clear pricing, lead time and any technical suggestions before production.